創楽【車カスタム】

Weber carb DCOE overhaul

②Float・needle

Weber DCOE overhaul

Category

| ①First・Venturi effect | ②Float・needle | ③Idling process |

| ④Pump・main process | ⑤Starter process | ⑥Summary |

創楽【車カスタム】ウェーバーキャブDCOE

カテゴリー

| セッティング | オーバーホール | 外車のセッティング数値 |

| 国産車のセッティング数値 | サニー 取付け例 | ハーレー 取り付け例 |

| ミツバ フェーエルポンプ | S20 ソレックスデータ | |

| ウェーバーDCOEホーム | 創楽・車カスタムホーム | 創楽・ホーム |

overhaul

float

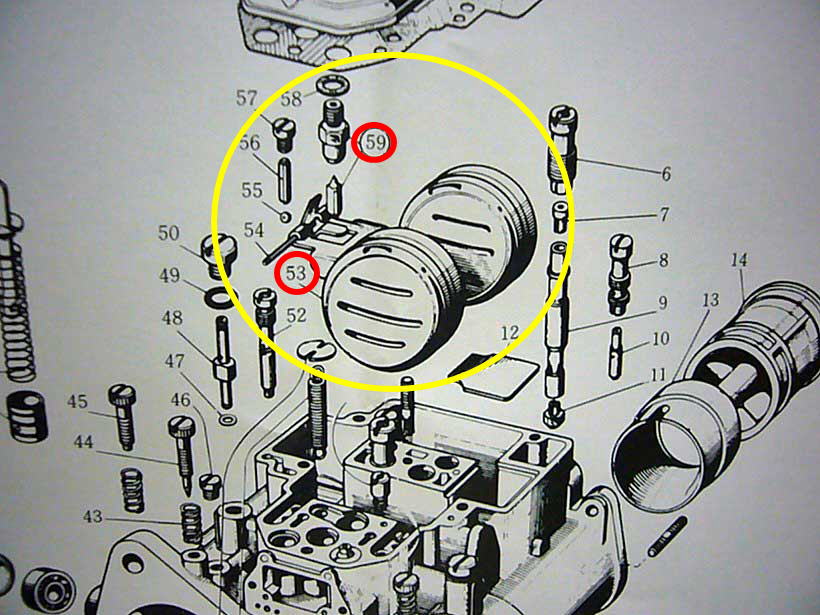

From the previous page,

When confirmation of the fail filter is

finished it is confirmation of the carburetor

upper float diagram No. 53 needle · figure 59.

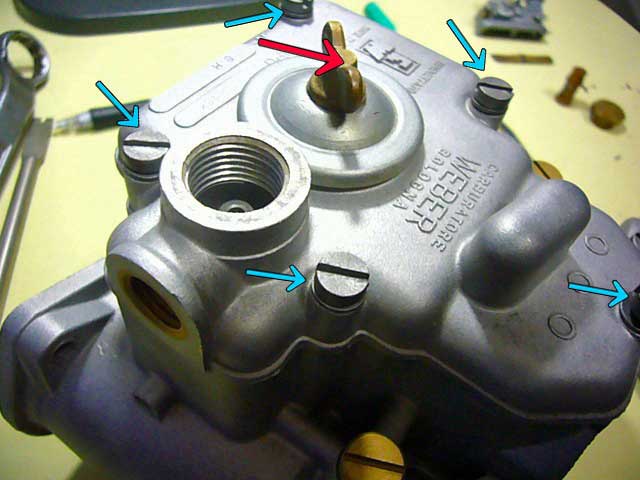

Then, remove the top of the Weber

carburetor. First remove the photo (red arrow)

jet cover and with a flat head screwdriver

(blue arrow) remove 5 bolts. I think

that it is good to remove it on the diagonal.

Even if the bolt is loosened, when the

carburetor cover does not come off, when

light shock is applied such as plastic hammer

It may get out.

Putting in too much power is not permitted.

Remove 5 bolts, remove the carburetor cover

I will take it out. Please do not give a

shock to the float of the picture (yellow arrow).

Float and cover connected Figure № 54

Perform from the process of removing

the float pin (yellow arrow).

To remove the pin, with a thin flathead screwdriver,

As shown in the photo, put it in the cover slit a little wider.

Attention, since this part is a very weak part,

If you put too much strength it will

crack. Please do not panic carefully.

Even if it does not spread

out, the pin may come off.

Because it is a severe part, please

perform it only when there is no coming off

As it is, extrude with a Phillips screwdriver

etc. from the opposite side as shown in the picture.

Lubricating oil etc. If you make it easy to slide,

the work will be easy.

When the pin comes out to the

extent that it can be pulled out with pliers,

Pull out slowly with pliers.

Hold the float (yellow arrow)

Do not stress on parts of

Pull out the pin carefully

(Yellow arrow) part is

It is an important part to

determine the float position.

You can now remove the float.

overhaul

needle

Remove float and gasket,

It is in a state with only a

needle valve attached.

Remove the needle valve from now.

Needle valve is 10 mm

It can be removed with a wrench.

Briefly explaining the needle valve,

Fuel enters the float room and the float lifts

This (yellow arrow) part is lifted

Stop fuel supply.

During traveling, the float will s

ink for the amount of fuel decrease

The needle opens and fuel is supplied.

During driving, the height of t

he fuel in the float room

It is important to keep constant

At this time, the size of the needle valve becomes

Make sure it is suitable for the installation engine.

Check the size

This way

A contact for stopping the supply of the needle valve,

Confirm whether there is a reduction stepped.

After finishing checking the

size and wear of the needle valve,

Reassemble.

When installing the float, put a new gasket

Please install from. Please check the

mounting direction of the float

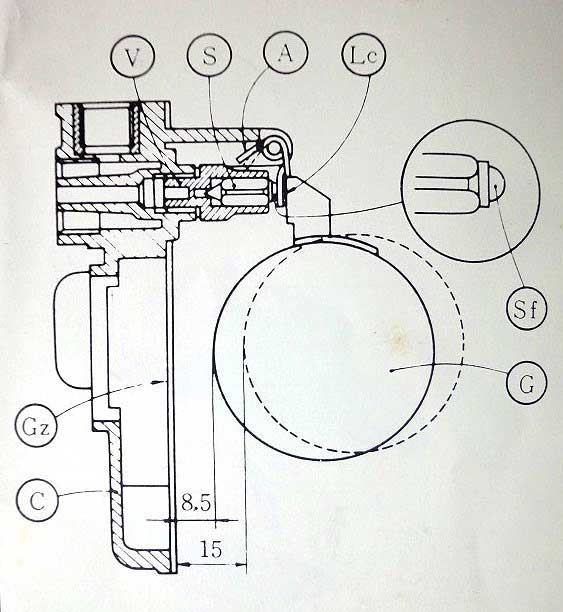

Confirm float position

As shown in the figure, the float rises and the needle valve

The closed height is 8.5 mm · the sunken height is 15 mm

It is in the commentary.

Although this height is also introduced to

Weber carburetor standard setting, the height

may be different for each vehicle.

Because this adjustment is difficult

It was confirmed only.

It looks like you are checking the

height of the float with a vernier caliper.

When this is done, the upper

part of the carburetor is finished.

Next we will enter the main body.

| ③Idling process |

Weber DCOE overhaul

Category

| ①①First・Venturi effect | ②Float・needle | ③Idling process |

| ④Pump・main process | ⑤Starter process | ⑥Summary |

創楽【車カスタム】ウェーバーキャブDCOE

カテゴリー

| セッティング | オーバーホール | 外車のセッティング数値 |

| 国産車のセッティング数値 | サニー 取付け例 | ハーレー 取り付け例 |

| ミツバ フェーエルポンプ | S20 ソレックスデータ | |

| ウェーバーDCOEホーム | 創楽・車カスタムホーム | 創楽・ホーム |

55